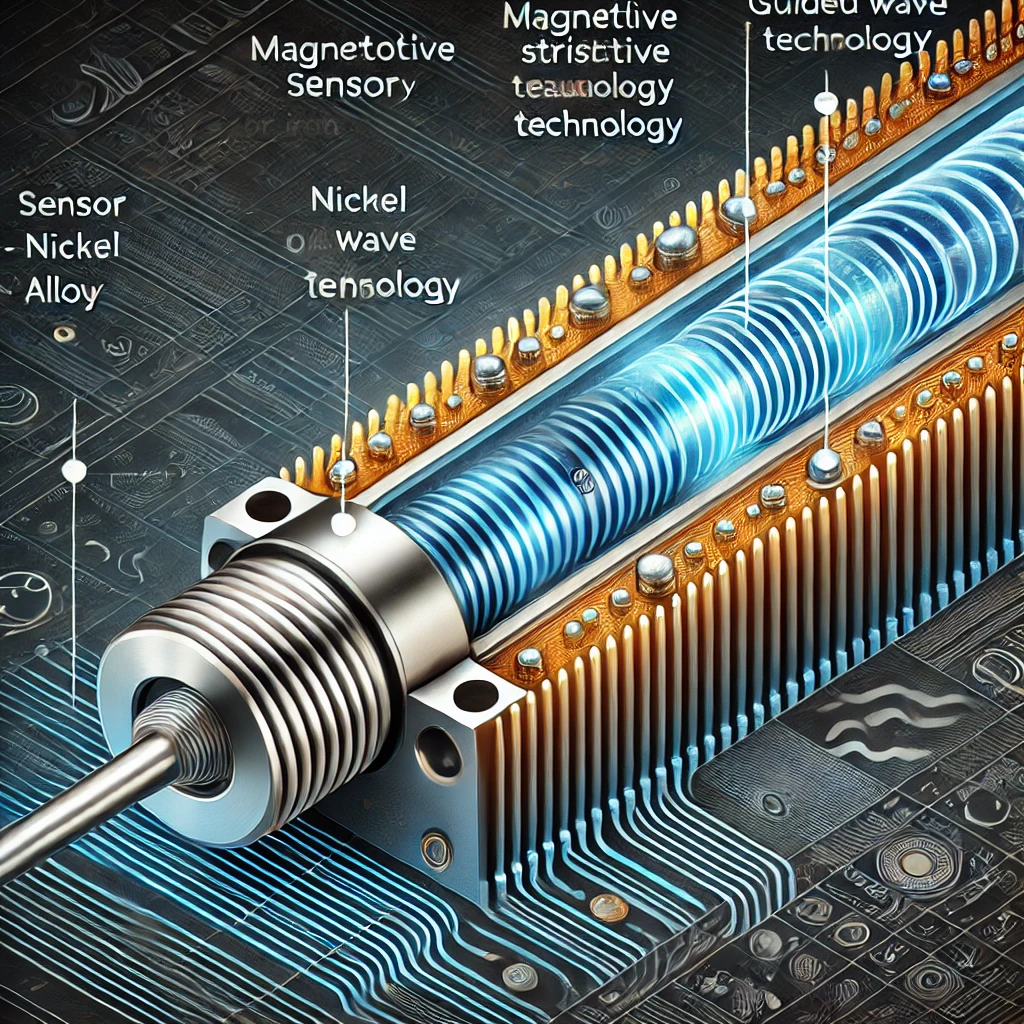

Magnetostrictive sensor technology is a highly reliable method used for precise position and speed measurement. It operates based on the physical principle where certain materials change shape or dimensions when exposed to a magnetic field. This change is detected and measured, providing highly accurate readings.

Table of Contents

How Does Magnetostrictive Sensor Technology Work?

Magnetostrictive sensors function by using a magnetized rod, usually made of a nickel or iron alloy, that reacts to a magnetic field. When a current is sent through the material, it produces a mechanical wave known as a guided wave. This wave travels through the material, and the time it takes to return is measured to determine the exact position of an object.

The Role of the Guided Wave

The guided wave is critical to magnetostrictive sensor operation. It ensures that the measurements are precise by tracking the time delay between the generation and return of the wave. The sensor calculates the exact position or speed of the moving object based on this time measurement.

Key Benefits of Magnetostrictive Sensor Technology

Magnetostrictive sensors offer many advantages, making them ideal for industrial applications where high accuracy and durability are essential.

High Accuracy and Reliability

One of the primary benefits of using magnetostrictive sensors is their unmatched accuracy. The guided wave allows for precise measurements, even in challenging conditions such as extreme temperatures or environments with high vibration. This makes them reliable for industries like manufacturing and automation.

Non-Contact Measurement

Since these sensors operate through magnetic fields, there is no need for direct contact between the sensor and the object being measured. This non-contact measurement ensures that the system experiences minimal wear and tear, extending its lifespan.

Durability in Harsh Environments

Magnetostrictive sensors are also known for their durability. They can operate effectively in harsh environments, including areas exposed to chemicals, dust, and moisture. Their rugged design allows them to perform consistently without being affected by external factors.

Applications of Magnetostrictive Sensor Technology

Magnetostrictive sensor technology has a wide range of applications across various industries. Its ability to provide accurate, real-time data makes it indispensable in many sectors.

Industrial Automation

In industrial automation, magnetostrictive sensors are commonly used to monitor and control the position of machine parts. This ensures smooth operation and helps prevent breakdowns by providing real-time data on machine performance.

Robotics

Robotic systems also benefit from magnetostrictive sensors. They help robots move with precision, enabling them to carry out tasks such as assembly, welding, and material handling with high accuracy.

Hydraulic and Pneumatic Systems

Magnetostrictive sensors are often used in hydraulic and pneumatic systems to measure the position of cylinders. By providing exact position feedback, these sensors help improve the efficiency and safety of these systems.

Conclusion: The Future of Magnetostrictive Sensors

Magnetostrictive sensor technology with guided wave is proving to be a game-changer in precision measurement. Its high accuracy, reliability, and durability make it ideal for a variety of industrial applications. As technology evolves, we can expect even more advancements in magnetostrictive sensors, making them more efficient and accessible for modern industries.

This non-contact, precise measurement solution will continue to play a significant role in automation, robotics, and other fields that demand consistent performance and longevity.